Capacitor Types: Difference between revisions

| Line 5: | Line 5: | ||

=== Identification === | === Identification === | ||

These are the most common type of failed capacitor and have been the most widely used. They may come as a through hole part with pins that extend through the board or as surface mount with legs that are soldered flush. They are cylindrical with the through hole versions having a sleeve over the "can" with the markings printed on it and the SMD versions being metal with direct printing in black. The position of the pins is can be different with radial having them both on one side and axial having them on opposite ends. For some axial capacitors, in audio applications mostly, you may additionally encounter bipolar capacitors. | These are the most common type of failed capacitor and have been the most widely used. They may come as a through hole part with pins that extend through the board or as surface mount with legs that are soldered flush. They are cylindrical with the through hole versions having a sleeve over the "can" with the markings printed on it and the SMD versions being metal with direct printing in black. The position of the pins is can be different with radial having them both on one side and axial having them on opposite ends. For some axial capacitors, in audio applications mostly, you may additionally encounter bipolar capacitors. | ||

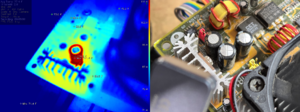

[[File:Hot-cap.png|thumb|An electrolytic capacitor that is not visually leaking or bulging but is running much hotter than the surrounding parts, including the identical capacitor above it.]] | |||

=== Polarity === | === Polarity === | ||

Polar. Negative side on electrolytic capacitors is marked. Some audio applications use bi-polar capacitors that are non-polar | Polar. Negative side on electrolytic capacitors is marked. Some audio applications use bi-polar capacitors that are non-polar | ||

| Line 15: | Line 16: | ||

=== Information === | === Information === | ||

Electrolytic capacitors have a fluid that acts as a conductor to the cathode but also serves to maintain a dielectric layer with the anode. The anode is a sheet of aluminum rolled up inside of the can. The dielectric is formed as an oxide layer where the electrolyte contacts the anode and a voltage across the capacitor consumes electrolyte to "heal" the dielectric. Because of the chemistry of how the dielectric is maintained these capacitors are "polar" meaning they have positive and negative sides that must be connected to the higher and lower voltages respectively. Getting this backwards can be disastrous. Bi-polar caps are a essentially a hybrid part with two capacitors connected to each other and are non-polar as a result. | Electrolytic capacitors have a fluid that acts as a conductor to the cathode but also serves to maintain a dielectric layer with the anode. The anode is a sheet of aluminum rolled up inside of the can. The dielectric is formed as an oxide layer where the electrolyte contacts the anode and a voltage across the capacitor consumes electrolyte to "heal" the dielectric. Because of the chemistry of how the dielectric is maintained these capacitors are "polar" meaning they have positive and negative sides that must be connected to the higher and lower voltages respectively. Getting this backwards can be disastrous. Bi-polar caps are a essentially a hybrid part with two capacitors connected to each other and are non-polar as a result. | ||

== Polymer == | == Polymer == | ||

=== Identification === | === Identification === | ||

Revision as of 23:01, 3 November 2024

Capacitors come in many varieties that can differ not only physically but chemically, electrically, and mechanically as well. It is possible to substitute some kinds of capacitors with others, but not always, and it may not always be practical or a good idea. Here are some of the different kinds of more common capacitors you may encounter

Electrolytic/Aluminum/Wet

Identification

These are the most common type of failed capacitor and have been the most widely used. They may come as a through hole part with pins that extend through the board or as surface mount with legs that are soldered flush. They are cylindrical with the through hole versions having a sleeve over the "can" with the markings printed on it and the SMD versions being metal with direct printing in black. The position of the pins is can be different with radial having them both on one side and axial having them on opposite ends. For some axial capacitors, in audio applications mostly, you may additionally encounter bipolar capacitors.

Polarity

Polar. Negative side on electrolytic capacitors is marked. Some audio applications use bi-polar capacitors that are non-polar

Significant Specifications (in order of importance)

- Capacitance

- Voltage

- Max Temperature

- ESR (equivalent series resistance)

- Ripple Current

Information

Electrolytic capacitors have a fluid that acts as a conductor to the cathode but also serves to maintain a dielectric layer with the anode. The anode is a sheet of aluminum rolled up inside of the can. The dielectric is formed as an oxide layer where the electrolyte contacts the anode and a voltage across the capacitor consumes electrolyte to "heal" the dielectric. Because of the chemistry of how the dielectric is maintained these capacitors are "polar" meaning they have positive and negative sides that must be connected to the higher and lower voltages respectively. Getting this backwards can be disastrous. Bi-polar caps are a essentially a hybrid part with two capacitors connected to each other and are non-polar as a result.

Polymer

Identification

Similar to electrolytic but are more likely to be only metal on the outside with the markings printed with a color instead of black. The SMD versions are most common but they are available in rectangular SMD parts and less commonly radial through hole. These group also includes some Tantalum capacitors which I've broken out to their own description.

Note: Würth Elektronik through-hole polymer capacitors use sleeves like their Aluminum Electrolytic capacitors.

Polarity

Polar. Negative side on can polymer capacitors is marked. Positive side on rectangular polymer capacitors is marked.

Significant Specifications (in order of importance)

- Capacitance

- Voltage

- Max Temperature

- ESR (equivalent series resistance)

- Ripple Current

Information:

There are a number of capacitors of different types in the categories so identification of exactly what kind it is will make replacing it correctly more effective. The can package versions of these capacitors are most likely to fail by leaking, especially earlier SMD examples. They can also fail short due to aging. Rectangular capacitors are more likely to increase in ESR until they either stop working, short, or pop. All of the polymer capacitors have reduced self "healing" capabilities compared to the wet aluminum electrolytic capacitors.

Tantalum

Identification

Rectangular SMD versions are typically larger than SMD resistors. Through hole versions will look dipped in a coating and may have three legs. All models commonly yellow, rectangular may be black and dipped may be blue.

Polarity

Polar. Positive side on rectangular and dipped tantalum capacitors is marked.

Significant Specifications (in order of importance)

- Capacitance

- Voltage

- Max Temperature

Information

These capacitors are more common in older devices when tantalum capacitors had higher energy densities and better ESRs than other capacitor technologies available at the time, however in newer devices those have been mostly replaced by modern high capacitance MLCCs. Tantalum capacitors can be more reliable in certain applications than other capacitors but do fail. They may fail gradually with slowly increasing leakage current and then eventually short from aging even without use, especially older ones. This failure mode can stress upstream regulation components causing excessive dissipation and damage or in catastrophic failure modes the capacitor can reach extreme temperatures damaging the PCB and adjacent components. Some may naturally fail open or low capacitance with how they deplete.

- Tantalum capacitors that failed short spectacularly .

-

-

-

Ceramic

Identification

SMD parts are brown and typically unlabeled. Through hole are a tan disc or square shaped

Polarity

Non-polar.

Significant Specifications (in order of importance)

- Capacitance

- Voltage

- Class (eg. X7R)

- Max Temperature

Information

These capacitors don't fail often. They are chemically simpler than other capacitors and don't have a wet electrolyte. Ceramic capacitors come in many different dielectric classes for example a common class is X7R, the best NP0 dielectrics are very reliable and do not appreciably age however they are limited to only very small capacitance, other dielectrics such as Y5V can age significantly after thousands of operating hours, larger capacitance MLCCs will typically use those more sensitive dielectric classes due to cost and size constraints and are thus more likely to fail. Mechanical failure due to excessive flexing of the PCB is often a failure mode of MLCCs, some MLCCs in high vibration applications (eg. automotive) will use 'soft terminations' to avoid catastrophic short circuit failures.

Paper

Identification

Can be very large and may look like cardboard. Smaller examples may be dipped in epoxy.

Polarity

Polar. Negative side marked, sometimes seen as "outside foil".

Significant Specifications (in order of importance)

- Capacitance

- Voltage

- Max Temperature

Information

Paper capacitors vary wildly in appearance and size. They can fail in extremely visible ways as they are susceptible to expansion and moisture intrusion. Paper capacitors were used in lots of older gear (especially anything to do with vacuum tubes) and the paper is failing, causing them to turn into resistors or become a dead short, destroying components. The epoxy coated examples may overheat and rapidly expand...or...explode. Exact replacements are likely not available. Some paper capacitors are also filled with oil, which are susceptible to leaking out and coating everything. It is recommended to replace paper capacitors with X 1/2 film capacitors or Y 1/2 ceramic disk capacitors.